Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing

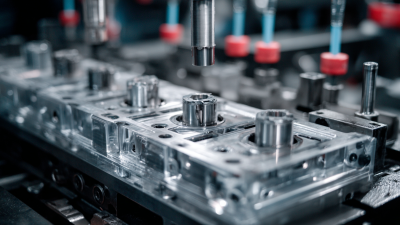

In the ever-evolving landscape of modern manufacturing, efficiency and precision are paramount, making the role of the injection molding die increasingly significant. This vital component not only streamlines the production process but also enhances the quality of the final product.

As industries strive to meet growing demands with minimal waste and maximum accuracy, understanding the benefits of injection molding die becomes essential. From reducing manufacturing costs to enabling complex designs, this tutorial aims to delve into the multifaceted advantages of injection molding die in contemporary manufacturing practices.

By unlocking the potential of this technology, manufacturers can not only improve operational efficiency but also gain a competitive edge in the market.

Join us as we explore how embracing injection molding die can transform production workflows and elevate product quality to new heights.

Advantages of Injection Molding Die Over Traditional Manufacturing Methods

Injection molding has revolutionized the manufacturing landscape, offering distinct advantages over traditional methods. According to a study by the American Society for Engineering Education, the precision and efficiency of injection molding allow manufacturers to produce parts in a matter of seconds, significantly reducing cycle times. While conventional manufacturing techniques can take hours or even days to complete complex parts, injection molding can achieve a production rate of up to 5,000 units per hour, enhancing overall productivity.

Moreover, injection molding dies support higher consistency and quality in production processes. A report from the Plastics Industry Association highlights that manufacturers can realize a reduction in scrap rates by up to 30% through the use of injection molding technologies. This is attributed to the ability to create intricate designs with minimal waste, a challenge often faced with traditional fabrication methods. As manufacturers continue to seek innovative solutions that optimize efficiency and sustainability, the shift towards injection molding is becoming increasingly evident.

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing

| Advantage | Injection Molding Die | Traditional Manufacturing |

|---|---|---|

| Production Speed | High-speed production, cycles typically in seconds | Slower production, cycles can take minutes to hours |

| Precision | High dimensional accuracy and uniformity | More variations in dimensions, requires more quality checks |

| Material Utilization | Minimal waste due to the closed system | Higher waste due to excess material trimming |

| Scalability | Easily scalable for mass production | Limited scalability, often requires retooling |

| Cost Efficiency | Lower cost per unit at high volumes | Higher cost per unit, especially at lower volumes |

| Complex Design Capability | Can produce intricate designs with ease | Limited capability for complex shapes |

Cost Efficiency: An In-Depth Comparison of Injection Molding Process

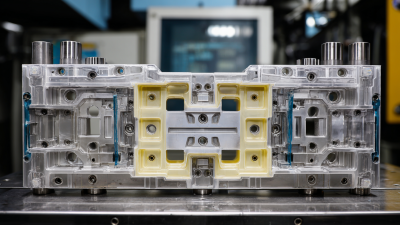

The injection molding process has emerged as a frontrunner in modern manufacturing due to its unparalleled cost efficiency. This technique allows for the mass production of complex parts with remarkable precision, which significantly reduces labor and material waste. By leveraging automated machinery, manufacturers can achieve economies of scale that traditional methods simply cannot match. As a result, businesses not only enjoy lower per-unit costs but also faster turnaround times, making them more competitive in the market.

Moreover, the initial investment in injection molding dies may seem substantial, but the long-term savings are undeniable. Once the die is created, the cost of producing each additional unit diminishes dramatically. This makes injection molding ideal for high-volume production runs, enabling manufacturers to remain agile and responsive to market demands. With continuous advancements in materials and technology, the injection molding process continues to evolve, driving costs down even further and unlocking new possibilities for a variety of industries.

Material Versatility: How Injection Molding Compares to Other Techniques

Injection molding has become a cornerstone of modern manufacturing, particularly due to its exceptional material versatility. Unlike traditional machining processes, which often limit manufacturers to metals and rigid plastics, injection molding accommodates a wide array of materials including thermoplastics, thermosets, elastomers, and even bioplastics. According to a report by the Plastics Industry Association, around 90% of all manufactured plastic parts are produced through injection molding, highlighting its dominant role in the industry.

When compared to other fabrication techniques, injection molding stands out for its efficiency and cost-effectiveness. A study from Grand View Research indicates that the global injection molding market is projected to reach USD 453.5 billion by 2027, driven largely by the technique’s ability to produce complex shapes efficiently while minimizing waste. Additionally, the ease of material integration allows manufacturers to blend materials, creating unique properties suited for specific applications, which is something other manufacturing methods struggle to achieve. This flexibility not only promotes innovation but also reduces time-to-market for new products, making injection molding an invaluable asset in contemporary production environments.

Production Speed: Evaluating Time Efficiency Across Different Methods

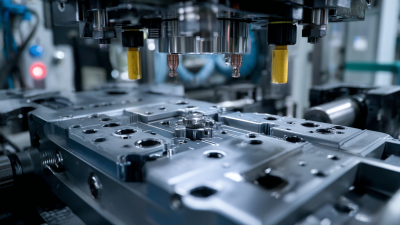

In the realm of modern manufacturing, production speed is a critical factor that often distinguishes successful processes from those that struggle. Injection molding die stands out as an exceptionally efficient method, particularly when compared to traditional manufacturing techniques such as machining or manual assembly. The design of injection molding allows for rapid production cycles, significantly reducing the time from concept to final product. This efficiency is largely due to the ability to create complex geometries in a single step, thus eliminating the need for multiple processing stages.

Moreover, the consistency and repeatability of injection molding enhance time efficiency even further. Once a die is created and optimized, it can produce thousands of identical parts with minimal variation, leading to reduced downtime and less waste. Traditional methods may require extensive retooling or adjustments which contribute to slower output. By leveraging injection molding die technology, manufacturers can not only speed up their production processes but also improve overall quality, allowing them to respond swiftly to market demands while maintaining rigorous standards.

Precision and Quality: A Comparative Analysis of Manufacturing Outcomes

Injection molding has revolutionized the way we approach manufacturing, particularly in achieving precision and quality. One of the key advantages of using injection molding dies is their ability to consistently produce parts that meet stringent tolerances. By leveraging advanced technologies and materials, manufacturers can create complex shapes with intricate details without compromising structural integrity. This uniformity in production not only minimizes waste but also shortens lead times, ensuring that products reach the market faster than traditional manufacturing methods.

Comparative analysis of manufacturing outcomes highlights the superiority of injection molding over other techniques such as CNC machining and 3D printing, especially for high-volume production. While CNC methods may offer high precision, they often fall short in efficiency and scalability. On the other hand, 3D printing is great for prototyping but struggles to maintain the quality and durability required for mass production. Injection molding emerges as the optimal solution, providing a fine balance between precision and efficiency, enabling manufacturers to deliver high-quality products reliably and economically.

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing

Related Posts

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

China's Premier Plastic Injection Tooling Solutions for a Global Market