Achieving the Best Plastic Injection Molding Mold Standards Through Effective Design Techniques

In the ever-evolving landscape of manufacturing, achieving excellence in plastic injection molding mold standards is crucial for competitive success. According to the "2019 Global Plastic Injection Molding Market Report," the industry is projected to reach $300 billion by 2025, underscoring the significance of stringent quality and design techniques. The effectiveness of these techniques not only enhances mold durability and efficiency but also ensures compliance with international import and export certifications, which are vital for companies looking to expand in global markets. Enhanced design methodologies can play a pivotal role in minimizing defects and reducing cycle times, ultimately streamlining production processes. By focusing on design precision and leveraging advanced technologies, manufacturers can meet and exceed the high standards expected in the plastic injection molding mold sector, positioning themselves favorably amidst growing market demands.

Understanding Plastic Injection Molding: Key Design Principles for Success

Understanding the intricacies of plastic injection molding is essential for achieving success in the industry. At its core, this process involves injecting molten plastic into a mold to create specific shapes and designs. One of the key design principles that significantly impacts the effectiveness of molding is the choice of materials. Selecting the right type of plastic not only influences the final product's strength and durability but also determines how well the material flows into the mold. Understanding the thermal properties and viscosity of the chosen plastic can lead to better designs that minimize waste and enhance efficiency.

Another crucial design aspect is the geometry of the part being produced. Designing parts with uniform wall thickness helps avoid issues like warping or defects during cooling. Additionally, integrating features such as draft angles can facilitate easier ejection from the mold, reducing the risk of damage to both the part and the mold itself. By prioritizing these essential design principles, manufacturers can improve the reliability and quality of their plastic products, leading to a more streamlined production process and greater customer satisfaction.

Selecting the Right Materials: Enhancing Mold Performance and Longevity

Selecting the right materials for plastic injection molding is crucial for enhancing mold performance and longevity. The choice of material directly affects the durability, heat resistance, and overall effectiveness of the mold. For instance, using high-quality steel alloys can significantly improve the lifespan of the mold, reducing wear and tear over time. Additionally, incorporating materials with high thermal conductivity can facilitate better heat dissipation, leading to shorter cycle times and improved product quality.

Tips: Always consider the specific requirements of your project when selecting materials. Analyze factors such as chemical resistance, temperature, and pressure conditions to ensure compatibility. It’s also beneficial to consult with material suppliers who can provide insights into the best options available for your needs.

Another important aspect involves the use of coatings or surface treatments that can enhance mold performance. These treatments can reduce friction, improve release properties, and protect the mold from corrosion. By applying such enhancements, manufacturers can achieve longer-lasting molds that require less maintenance and result in consistent product output.

Tips: Before finalizing any coatings, conduct thorough testing to assess their effectiveness under production conditions. Keep in mind that investing in superior materials and treatments not only leads to enhanced mold performance but also reduces the total cost of ownership over time.

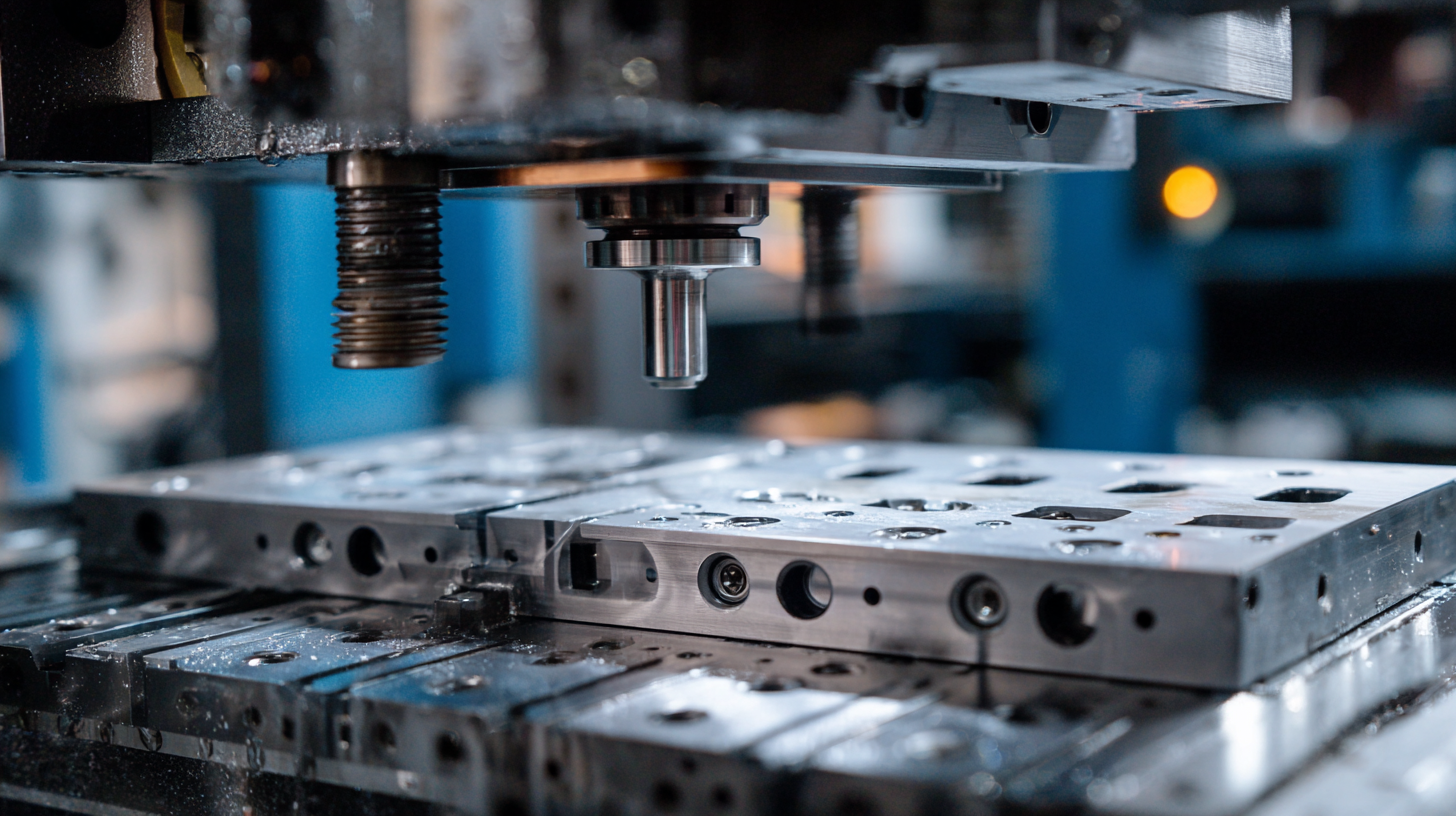

Streamlining the Injection Process: Techniques for Improved Efficiency

In the realm of plastic injection molding, streamlining the injection process is paramount to improve efficiency and reduce production costs. One effective technique involves optimizing the mold design to enhance material flow. By strategically positioning gates and vents, manufacturers can minimize pressure loss and prevent issues such as short shots or warpage. Advanced simulation tools can be employed to visualize flow dynamics, allowing designers to anticipate potential problems and make necessary adjustments before the mold is even built.

Another crucial aspect is the selection of appropriate materials and processing conditions. By choosing the right resin and adjusting parameters such as temperature, pressure, and injection speed, manufacturers can achieve smoother transitions and faster cycle times. Furthermore, implementing automation in the injection process can significantly reduce manual intervention, ensuring consistency and accuracy. This approach not only enhances overall productivity but also leads to a more sustainable manufacturing process by minimizing waste and energy consumption.

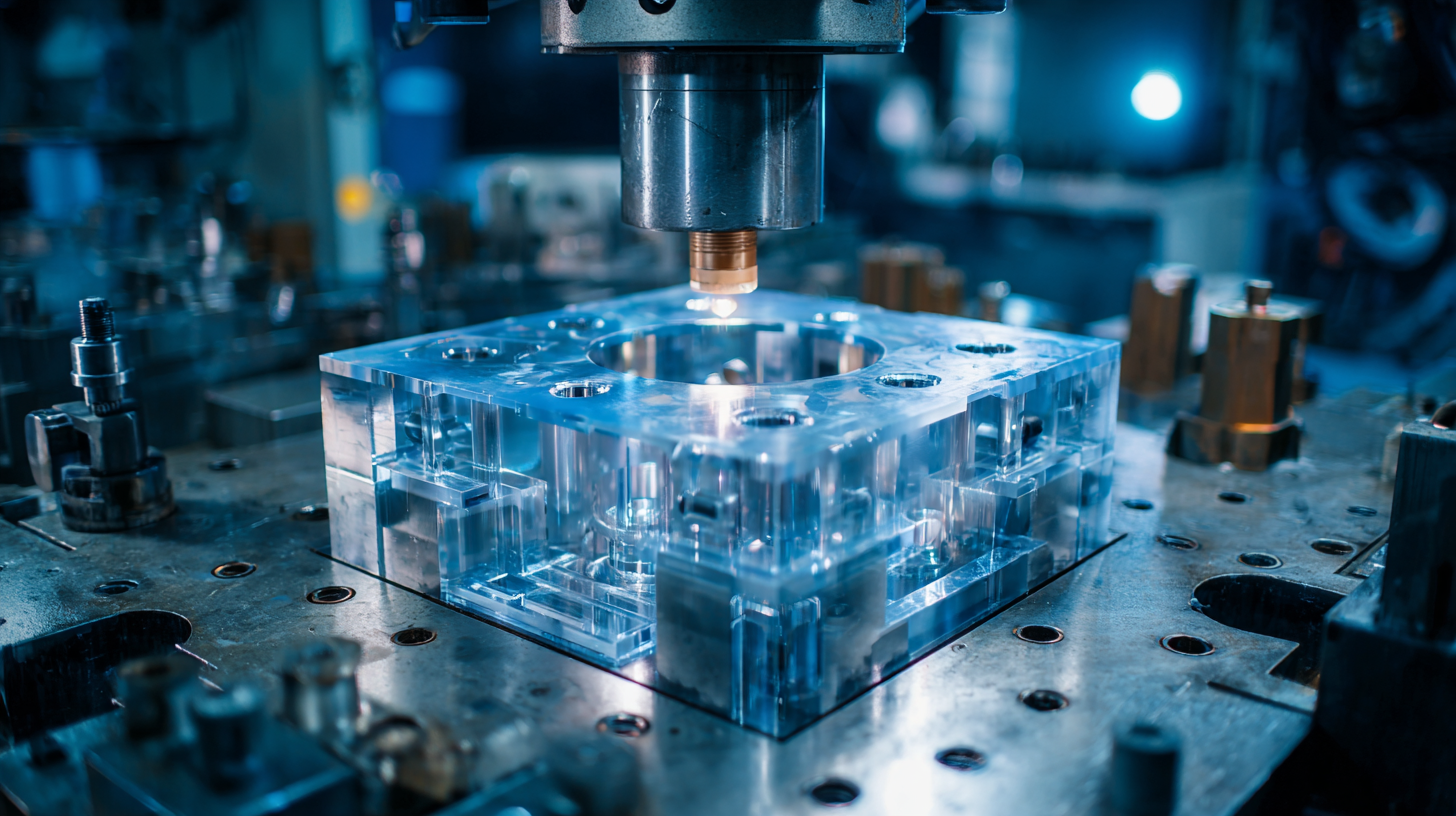

Innovative Design Features: Maximizing Production Quality and Reducing Costs

Innovative design features play a crucial role in maximizing production quality and reducing costs in plastic injection molding. According to a report by the Society of Plastics Engineers, up to 80% of manufacturing costs can be influenced by design decisions made in the early stages. By implementing advanced design techniques such as computer-aided engineering (CAE) and simulation, companies can foresee potential issues and optimize their molds before production begins. This proactive approach not only enhances product quality but also minimizes costly revisions and downtime during manufacturing.

Innovative design features play a crucial role in maximizing production quality and reducing costs in plastic injection molding. According to a report by the Society of Plastics Engineers, up to 80% of manufacturing costs can be influenced by design decisions made in the early stages. By implementing advanced design techniques such as computer-aided engineering (CAE) and simulation, companies can foresee potential issues and optimize their molds before production begins. This proactive approach not only enhances product quality but also minimizes costly revisions and downtime during manufacturing.

Incorporating design features like parting line optimization and using conformal cooling channels has been shown to significantly improve production efficiency. A study published in the "Journal of Injection Molding Technology" highlights that molds with conformal cooling can reduce cycle times by as much as 30%, leading to an increase in output without compromising quality. Furthermore, the integration of smart manufacturing technologies, including real-time monitoring and data analytics, provides manufacturers with actionable insights to further drive down costs while ensuring adherence to the highest quality standards. By embracing these innovative designs, companies can achieve a competitive edge in the plastic injection molding industry.

Best Practices for Testing and Validation: Ensuring Mold Standards Are Met

To ensure that mold standards are consistently met in plastic injection molding, best practices for testing and validation are crucial. Starting with thorough initial inspections, molds should undergo rigorous evaluations to assess their structural integrity and precision.

Techniques such as 3D scanning and dimensional measurements can identify potential flaws early on, allowing for adjustments before production begins. This proactive approach minimizes the risk of defects in the final products and ensures that the mold design adheres to specified requirements.

In addition to pre-production assessments, ongoing testing throughout the injection molding process can significantly enhance quality assurance. Utilizing methods like pressure and temperature monitoring, manufacturers can detect anomalies in real time, preventing costly downtime and waste. Furthermore, implementing a feedback loop from production to design can improve future mold iterations, fostering a culture of continuous improvement. By prioritizing these testing and validation practices, companies can achieve optimal mold standards, leading to enhanced product quality and customer satisfaction.