China's Premier Plastic Injection Tooling Solutions for a Global Market

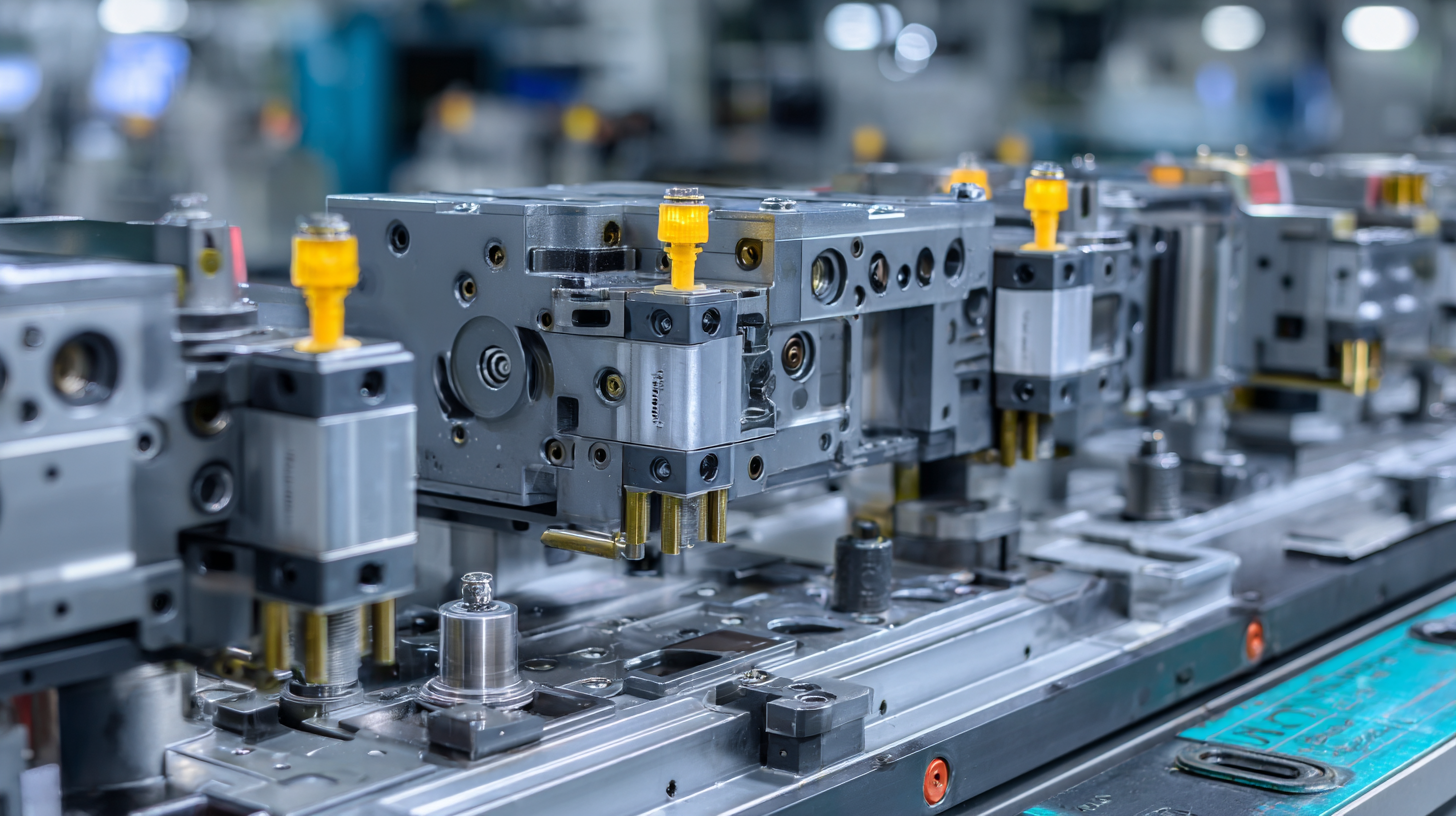

In today’s fast-paced global market, the demand for efficient and high-quality manufacturing processes is ever-increasing, making plastic injection tooling a critical component in various industries.

China's premier plastic injection tooling solutions stand out due to their innovative designs, advanced technology, and cost-effectiveness. By leveraging a skilled workforce and modern manufacturing techniques, Chinese companies have positioned themselves as leaders in the field, offering a diverse range of tooling options that cater to international standards. The benefits of investing in these solutions are substantial, including reduced production time, enhanced product consistency, and the ability to accommodate complex designs. This blog will explore the numerous advantages that China's plastic injection tooling offers to businesses worldwide, highlighting its pivotal role in driving efficiency and competitiveness in the global marketplace.

China's premier plastic injection tooling solutions stand out due to their innovative designs, advanced technology, and cost-effectiveness. By leveraging a skilled workforce and modern manufacturing techniques, Chinese companies have positioned themselves as leaders in the field, offering a diverse range of tooling options that cater to international standards. The benefits of investing in these solutions are substantial, including reduced production time, enhanced product consistency, and the ability to accommodate complex designs. This blog will explore the numerous advantages that China's plastic injection tooling offers to businesses worldwide, highlighting its pivotal role in driving efficiency and competitiveness in the global marketplace.

China's Rise as a Leader in Plastic Injection Tooling Manufacturing

As the global demand for plastic products continues to rise, China's position as a leader in plastic injection tooling manufacturing becomes increasingly prominent. In 2021, the global plastic injection molding market was valued at approximately $305 billion, with China accounting for nearly 30% of this figure. This growth is fueled by advancements in technology, skilled labor, and cost-effective production methods, which allow Chinese manufacturers to produce high-quality tools at competitive prices.

When selecting plastic injection tooling solutions, companies should consider a few tips: First, look for manufacturers that utilize advanced manufacturing technologies, such as CNC machining and additive manufacturing, as they can enhance precision and efficiency. Second, evaluate the supplier's experience in catering to various industries, as versatility often indicates a robust understanding of different requirements and standards. Lastly, prioritize firms that maintain strong quality control processes, which can prevent costly errors and delays in production.

China's committed investment in research and development is also a crucial factor contributing to its dominance in this sector. The country is expected to maintain its leadership, with projections indicating that the plastic injection molding market will reach around $500 billion by 2027. As Chinese manufacturers continue to innovate and meet the demands of a global market, their expertise in plastic injection tooling will undoubtedly play a pivotal role in shaping the future of manufacturing.

The Global Demand Surge: Key Markets Spurring Chinese Tooling Growth

The global demand for plastic injection tooling solutions is growing significantly, driven by a surge in key markets around the world. According to industry forecasts, the global metal cutting tools market is expected to grow from $86.24 billion in 2025 to $141.65 billion by 2032, reflecting a compound annual growth rate (CAGR) of 7.3%. This upward trend illustrates the increasing investment in advanced manufacturing technologies, which includes plastic injection tooling, as industries strive for greater efficiency and product customization.

Additionally, the global dentistry market for mobile dental tools is also witnessing expansion, projected to increase from $970 million in 2025 to $1.33 billion by 2032 with a CAGR of 4.6%. This growth is indicative of rising healthcare standards and the demand for innovative medical tools, further enhancing the opportunities for Chinese tooling manufacturers. As these markets evolve, China's premier plastic injection tooling solutions are well-positioned to meet the diverse needs of a rapidly changing global landscape.

Technological Innovations Transforming China's Injection Molding Sector

China's injection molding sector is undergoing an unprecedented transformation, driven by technological innovations that enhance efficiency and precision. According to a recent report by Mordor Intelligence, the Chinese injection molding machine market is expected to grow at a CAGR of 5.1% from 2021 to 2026. This growth is largely attributed to advancements in automation and smart manufacturing technologies, which enable manufacturers to produce higher-quality products at lower costs.

One significant innovation is the adoption of Industry 4.0 principles, where Internet of Things (IoT) devices are integrated into molding machines, allowing for real-time monitoring and predictive maintenance. This not only reduces downtime but also minimizes material waste. The China Plastics Industry Association reports that implementing these smart technologies can boost productivity by up to 30%, allowing companies to stay competitive in the global market.

Furthermore, the shift towards sustainable practices is reshaping the landscape. The use of bioplastics and the implementation of energy-efficient machinery are gaining momentum, with research indicating that these environmentally friendly solutions are likely to capture 20% of the market share by 2025. As China continues to innovate, its injection molding sector is poised to lead in both productivity and sustainability, setting new benchmarks for the global industry.

Quality Standards in China's Plastic Injection Tooling: Meeting Global Expectations

China has established itself as a powerhouse in the plastic injection tooling industry, driven by a commitment to quality standards that align with global expectations. This focus on quality has become a defining characteristic of Chinese manufacturers, allowing them to compete effectively in the international market. By adhering to rigorous quality control processes and integrating advanced technologies, Chinese companies are producing tooling solutions that not only meet but often exceed the stringent requirements set by global clients.

The emphasis on quality standards is not merely about compliance; it reflects a cultural shift towards excellence in manufacturing. Chinese tooling manufacturers are increasingly investing in certifications and quality management systems such as ISO 9001, which instills confidence among international customers. With their ability to deliver precision tooling that ensures efficiency and reliability, these manufacturers are gaining traction worldwide, proving that China is not just a hub for low-cost production but also a leader in quality injection tooling solutions.

Sustainability Trends in China's Manufacturing: Eco-Friendly Practices in Tooling

Sustainability has become a key focus in China's manufacturing sector, particularly in the realm of plastic injection tooling. As global market demands shift towards eco-friendly practices, Chinese manufacturers are increasingly adopting sustainable solutions. According to the "2023 Sustainability in Manufacturing Report," over 70% of manufacturers in China are investing in greener technologies, highlighting a significant trend in the industry. This shift not only reduces environmental impact but also often leads to cost savings through improved efficiency and waste reduction.

One effective approach to enhance sustainability in tooling is the implementation of advanced materials. For instance, bioplastics and recyclables are becoming popular alternatives in production processes. Using these materials can decrease reliance on fossil fuels, which aligns with the goals outlined in China's 14th Five-Year Plan for promoting sustainable economic growth. Additionally, adopting precision injection molding techniques can drastically minimize waste, achieving production efficiencies that are both economically and ecologically beneficial.

Tip: Exploring partnerships with suppliers who prioritize sustainability can lead to better material options and innovative tooling solutions. Another tip is to invest in training for your workforce on eco-friendly practices, as a well-informed team can actively contribute to maintaining sustainable operations in the manufacturing process.