How to Choose the Right Injection Tooling for Your Manufacturing Needs

In the realm of modern manufacturing, the selection of the right injection tooling is crucial for optimizing production efficiency and product quality. According to a report by Grand View Research, the global injection molding market size was valued at approximately $218.6 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 5.0% from 2021 to 2028. This growth underscores the increasing importance of advanced injection tooling solutions that cater to evolving industry demands. Factors such as material compatibility, cost-effectiveness, and production scalability must be carefully considered to ensure that manufacturers can meet quality standards while minimizing waste and maximizing throughput. By understanding the nuances of injection tooling, businesses can make informed decisions that enhance their operational capabilities and align with market trends, ultimately securing a competitive edge in a fast-paced industry.

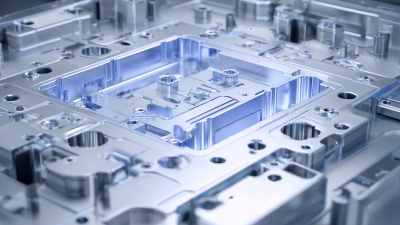

Understanding Different Types of Injection Tooling Used in Manufacturing

When selecting the right injection tooling for manufacturing, it's essential to understand the various types available and their applications. Traditionally, there are two main categories of injection tooling: single-cavity and multi-cavity molds. Single-cavity molds produce one part per cycle, offering lower initial costs and simplicity, making them ideal for prototypes or low-volume production. In contrast, multi-cavity molds can produce several parts simultaneously, significantly increasing output and efficiency. According to a recent report by Grand View Research, the global injection molding market is expected to reach $463.2 billion by 2028, highlighting the critical role tooling plays in meeting production demands.

Additionally, advancements in tooling technology, such as the use of hot runner systems, have revolutionized the injection molding process. Hot runner systems minimize waste by keeping the plastic in the runners molten, allowing for faster cycles and reduced material costs. A study by Research and Markets indicates that the adoption of hot runner systems can lead to a 15-20% reduction in cycle time, emphasizing the importance of choosing the right tooling to optimize manufacturing efficiency. Understanding the intricate details of these tooling options will empower manufacturers to make informed decisions that align with their production needs and goals.

How to Choose the Right Injection Tooling for Your Manufacturing Needs

| Tooling Type | Material Compatibility | Mold Life | Cost Range | Typical Applications |

|---|---|---|---|---|

| Aluminum Tooling | Thermoplastics | 50,000 - 100,000 cycles | $5,000 - $20,000 | Prototyping, Short Runs |

| Steel Tooling | Thermoplastics, Thermosets | 500,000 - 1,000,000 cycles | $20,000 - $100,000 | Mass Production |

| Hybrid Tooling | Thermoplastics | 100,000 - 500,000 cycles | $15,000 - $50,000 | Mid-Volume Production |

| Insert Molding | Thermoplastics, Metals | 100,000 + cycles | $30,000 - $150,000 | Complex Assemblies |

| Stack Molding | Thermoplastics | 200,000 - 1,000,000 cycles | $40,000 - $200,000 | Multi-Layer Products |

Key Factors to Consider When Selecting Injection Tooling

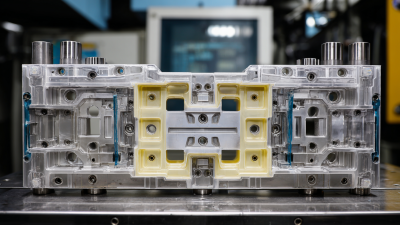

When selecting injection tooling for your manufacturing needs, several key factors come into play that can significantly impact the efficiency and quality of your production process. Firstly, the material of the tooling is crucial; different polymers have varying melting points and flow characteristics. Choosing a tooling material that can withstand the specific demands of your project's material will ensure durability and effectiveness. For example, tools made from hardened steel are ideal for high-volume production, while aluminum may be suitable for lower runs due to its cost-effectiveness.

Another critical consideration is the design and complexity of the tooling. The geometry of the part you are manufacturing influences the tooling design, including aspects like the number of cavities and the layout of cooling channels. A well-thought-out design not only optimizes the cycle time but also ensures consistent quality across all produced parts. Additionally, assessing the expected production volume is essential; high-volume runs may justify the investment in more sophisticated and robust tooling, whereas smaller batches might benefit from simpler, less expensive designs. Understanding these factors will help you make informed decisions that align with your manufacturing goals.

Key Factors to Consider When Selecting Injection Tooling

This chart represents the importance of various factors in choosing injection tooling for manufacturing needs based on industry insights.

The Role of Material Compatibility in Injection Tooling Selection

When selecting injection tooling for manufacturing, material compatibility plays a critical role. Using a tooling system that complements your chosen materials can significantly improve production efficiency and product quality. According to a recent industry report by Grand View Research, the global injection molding market is expected to reach $300 billion by 2025, indicating an increasing reliance on precision tooling that matches specific material properties. Understanding these properties, such as melting temperature and viscosity, is essential for optimizing your tooling selection.

Tip: Before choosing an injection tool, conduct thorough compatibility testing with your material. This can help identify any potential issues that may arise during production and ensure a smoother manufacturing process.

Moreover, the design of the tooling itself must align with the characteristics of the material being used. For instance, certain materials may require tooling with enhanced cooling channels or specialized coatings to prevent degradation. As noted by MoldMaking Technology, materials such as polycarbonate and nylon have unique processing requirements that can affect tooling life and performance.

Tip: Collaborate with material suppliers and tooling manufacturers early in the design phase to ensure that both tooling and material selections are well-integrated, ultimately saving time and reducing costs in the long run.

Evaluating Cost vs. Performance in Injection Tooling Choices

When selecting injection tooling for manufacturing, understanding the balance between cost and performance is crucial. According to a report from the 2022 Injection Molding Association, the average cost for injection molds ranges from $5,000 to $100,000, depending on complexity, materials, and manufacturing speed. While opting for lower-cost tools may seem economically enticing, it can lead to compromised quality and increased waste, ultimately affecting overall production efficiency.

Performance metrics, such as cycle time and part consistency, are equally critical in making a decision. A study by the Society of Plastics Engineers indicates that high-performance molds can reduce cycle times by up to 40%, translating directly to enhanced productivity and reduced operational costs over time. Investing in quality tooling may involve a higher upfront expenditure but yields significant long-term savings through decreased rework and scrap rates. Manufacturers should carefully evaluate their specific needs, weighing initial investments against potential performance benefits to make informed tooling choices that align with their production goals.

Common Mistakes to Avoid When Choosing Injection Tooling

When selecting injection tooling for your manufacturing needs, avoiding common pitfalls is crucial to ensuring a smooth production process. One frequent mistake is neglecting to thoroughly assess the material properties of the parts being produced. Different materials can significantly affect the tooling design, and overlooking this can lead to unexpected complications, such as poor mold flow or premature wear of the tooling.

Another critical error is underestimating the importance of mold maintenance and support. Many manufacturers focus solely on the initial cost and specifications of the tooling without considering the long-term implications of maintenance. Tools that are not designed for easy access or adjustment can lead to increased downtime and higher operational costs over time. Prioritizing tooling that facilitates straightforward maintenance will save time and resources, ensuring your manufacturing process remains efficient and cost-effective.

Related Posts

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

Innovative Injection Molding Design Examples to Inspire Your Next Project

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

7 Essential Reasons Why Best Injection Moldable Plastics Are Your Ultimate Solution

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions