7 Compelling Reasons to Choose Advanced Mold Manufacturing for Your Production Needs

In today's highly competitive manufacturing landscape, selecting the right partner for mold manufacturing is crucial for success. Advanced mold manufacturing not only enhances product quality but also optimizes production efficiency, giving businesses a significant edge. This ultimate guide will delve into the top seven compelling reasons why advanced mold manufacturing should be at the forefront of your production strategy.

From leveraging cutting-edge technologies to ensuring faster turnaround times, the benefits are manifold. By understanding the importance of precision and innovation in mold manufacturing, companies can make informed decisions that align with their goals and drive growth. Whether you're a seasoned manufacturer or just starting out, this guide will equip you with essential insights to elevate your production capabilities.

The Importance of Precision Engineering in Advanced Mold Manufacturing

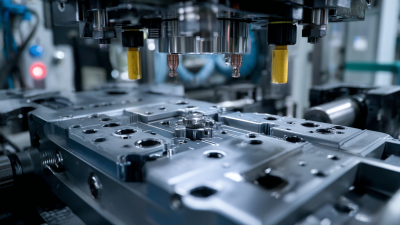

Precision engineering is a cornerstone of advanced mold manufacturing, playing a crucial role in ensuring high-quality production. In an industry where the smallest inaccuracies can lead to significant defects, precision becomes paramount. Advanced mold manufacturing combines sophisticated machining techniques with cutting-edge technology to produce molds that meet stringent specifications. This not only enhances the quality of the final product but also minimizes material waste, ultimately improving cost efficiency.

Moreover, precision engineering allows for intricate designs and complex geometries that are essential in today’s competitive market. With advanced computer-aided design (CAD) software and simulation tools, manufacturers can visualize and optimize their molds before they are even produced. This proactive approach reduces the likelihood of errors during production, saving time and resources. By choosing a manufacturer that prioritizes precision engineering, businesses can ensure that their mold production aligns perfectly with their innovative designs and functional requirements, leading to improved performance and customer satisfaction.

Enhancing Efficiency: The Role of Automation in Mold Production Processes

Automation in mold production processes is revolutionizing the industry, enabling manufacturers to enhance efficiency and reduce operational costs significantly. According to a report by MarketsandMarkets, the global market for industrial automation is expected to grow from $175 billion in 2019 to over $200 billion by 2024, highlighting a robust shift towards automated solutions. The integration of robotics and advanced software in mold manufacturing not only streamlines workflows but also minimizes the risk of human error, thereby increasing the overall quality and consistency of products.

Moreover, automated systems facilitate faster turnaround times, which is crucial in today’s competitive manufacturing environment. Data from the International Federation of Robotics reveals that companies implementing automation can reduce production cycle times by up to 30%. This increased efficiency allows businesses to respond more swiftly to market demands and innovate their product offerings without incurring significant additional costs. As manufacturers increasingly adopt these advanced technologies, the benefits will likely translate into better quality, higher production scales, and a stronger bottom line.

Cost-Effectiveness: Analyzing Long-Term Savings with Advanced Mold Solutions

When considering production needs, cost-effectiveness is a crucial factor that sets advanced mold manufacturing apart from traditional methods. These advanced solutions leverage cutting-edge technology and materials, resulting in molds that not only meet precise specifications but also have a longer lifespan. The durability of these molds significantly reduces the frequency of replacements, leading to substantial long-term savings. By investing in advanced mold manufacturing, companies can minimize their maintenance expenses and ensure smoother production processes.

Moreover, the efficiency of advanced mold solutions leads to faster turnaround times, allowing businesses to respond swiftly to market demands. The precision achieved with modern manufacturing techniques often results in reduced material waste, further enhancing cost efficiency. As companies gear towards larger production runs, the savings on both labor and material costs become increasingly evident. These factors contribute to a more sustainable financial model, where initial investments in advanced technology pay off over time, ultimately fostering growth and competitiveness in a rapidly evolving market.

7 Compelling Reasons to Choose Advanced Mold Manufacturing for Your Production Needs - Cost-Effectiveness: Analyzing Long-Term Savings with Advanced Mold Solutions

| Reason | Short-term Cost | Long-term Savings | Production Efficiency | Maintenance Costs |

|---|---|---|---|---|

| High-Quality Mold Design | $10,000 | $50,000 over 5 years | Increases by 30% | $1,000/year |

| Durability of Materials | $8,000 | $40,000 over 5 years | Increases by 25% | $800/year |

| Rapid Prototyping Capability | $15,000 | $60,000 over 5 years | Increases by 40% | $1,500/year |

| Advanced Automation Techniques | $12,000 | $45,000 over 5 years | Increases by 35% | $1,200/year |

| Scalability of Production | $20,000 | $70,000 over 5 years | Increases by 50% | $2,000/year |

Quality Assurance: The Impact of Advanced Materials on Mold Durability

When considering mold manufacturing, the choice of advanced materials can significantly impact mold durability and overall product quality. Advanced materials, such as sustainable fiber-reinforced composites, not only enhance the strength and lifespan of molds but also align with the growing trend towards eco-friendly manufacturing practices. As the demand for high-performance molds increases, incorporating innovative materials allows manufacturers to meet rigorous quality standards while also contributing to sustainability.

Tips for optimizing your production with advanced materials include: first, evaluate the specific requirements of your end products and select materials that offer the best balance between durability and flexibility. Second, stay updated on technological advancements, such as enhanced manufacturing technologies that improve mold design and effectiveness. Lastly, consider integrating machine learning models which can optimize injection molding processes, ensuring consistent quality and reducing waste.

Investing in advanced mold manufacturing is crucial for achieving superior results. The integration of state-of-the-art materials not only maximizes mold performance but also fosters a commitment to sustainable practices, which is essential in today’s market.

Sustainability Practices: How Advanced Mold Manufacturing Supports Eco-Friendly Production

Advanced Mold Manufacturing is paving the way for more sustainable production practices in the manufacturing industry. By incorporating eco-friendly materials and processes, companies can significantly reduce their environmental footprint. These practices not only align with global sustainability goals but also appeal to consumers who are increasingly conscious of the ecological impact of the products they purchase. By using recyclable and biodegradable materials, manufacturers can create molds that support a circular economy, ensuring that waste is minimized and resources are reused.

Moreover, Advanced Mold Manufacturing employs energy-efficient technologies that lower energy consumption during production. Techniques such as hot runner systems and optimized cooling channels reduce cycle times and energy use, demonstrating a commitment to eco-responsibility. Additionally, these innovations often lead to reduced emissions and lower waste generation, contributing to a cleaner environment. By prioritizing sustainability, companies in the mold manufacturing sector can enhance their brand reputation while also meeting the growing demand for environmentally-friendly products.

Related Posts

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Common Challenges in the Best Plastic Injection Moulding Process

-

The Future of Precision Injection Molding Innovations and Trends

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

Exploring Innovative Alternatives in Plastic Engineering Solutions

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes