How to Master the Art of Injection Mold Making for Your Business Success

In today's competitive landscape, the ability to master injection mold making is not just a technical skill; it’s a cornerstone for business success in the manufacturing sector. As industries increasingly demand precision and efficiency, the art of crafting high-quality molds has become essential for delivering superior products while optimizing production costs. Understanding the intricacies of injection mold making can empower businesses to innovate, reduce turnaround times, and meet consumer expectations effectively. In this blog, we will explore the critical steps and techniques involved in mastering this craft, highlighting best practices that can elevate your manufacturing processes and ultimately drive your business forward. Whether you are a seasoned professional or a newcomer, grasping the fundamentals of injection mold making will open doors to new opportunities and foster sustained growth in your enterprise.

Understanding the Basics of Injection Mold Making for Beginners

Injection mold making is a vital skill for those looking to enhance their manufacturing capabilities. For beginners, understanding the fundamentals can pave the way for business success. The process involves creating a mold into which molten plastic is injected, allowing for the production of complex shapes and components efficiently.

Injection mold making is a vital skill for those looking to enhance their manufacturing capabilities. For beginners, understanding the fundamentals can pave the way for business success. The process involves creating a mold into which molten plastic is injected, allowing for the production of complex shapes and components efficiently.

To effectively grasp the basics, it’s crucial to familiarize yourself with materials – both for the molds and the plastics used. High-quality steel or aluminum molds can significantly affect the durability and efficiency of the production process. Additionally, learning to analyze the importance of defect factors in the molding process can drastically improve output quality. Implementing techniques from methodologies like Six Sigma can help minimize defects and optimize operations.

Tips: Start by experimenting with DIY injection molding setups; numerous tutorials can guide you through building a simple machine. Additionally, consider leveraging new technologies such as predictive maintenance tools that use analytics to enhance machine performance, ensuring your processes are both efficient and effective as you dive deeper into the craft of injection mold making. Engaging in ongoing education through workshops or conferences focused on advanced techniques and emerging trends in the industry will also benefit your learning and growth in this field.

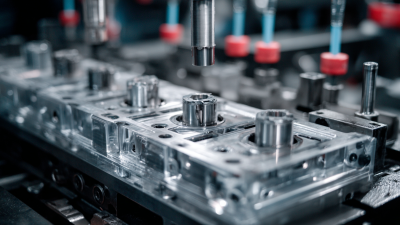

Essential Tools and Equipment for Efficient Mold Production

When it comes to injection mold making, having the right tools and equipment is crucial for efficiency and precision in production. One of the essential tools is the injection molding machine itself, which must be chosen based on the complexity and volume of parts you intend to produce. It is important to consider factors such as clamping force, shot size, and cycle times while selecting a machine that fits your business needs.

In addition to the molding machine, a high-quality mold design software is vital in optimizing the design process and reducing errors. This software allows for detailed modeling and simulation, enabling manufacturers to foresee potential issues and make necessary adjustments before the mold is even created. Moreover, ancillary equipment like hot runners and temperature control systems can significantly enhance the quality and consistency of the final product, minimizing waste and downtime. Investing in these essential tools not only streamlines production but also increases overall profitability for your business.

Key Techniques for Designing High-Quality Injection Molds

Mastering the art of injection mold making requires a deep understanding of key techniques that ensure the production of high-quality molds. The precision and performance of plastic components are paramount, especially in industries that demand rigorous standards. One of the critical aspects involves selecting the right materials, such as engineering plastics that offer strength and durability, to withstand the demands of various applications.

In recent trends, advancements in manufacturing technologies have transformed the injection molding landscape. Companies are investing in state-of-the-art CNC machining and assembly equipment to optimize their production processes. This shift not only enhances efficiency but also ensures that businesses can meet the increasing demand for high-performance injection molds. By implementing integrated strategies that focus on innovation and quality control, manufacturers are better positioned to compete in the global market, driving their success further.

Common Challenges in Injection Mold Making and How to Overcome Them

Injection mold making is a complex process that often presents several challenges to businesses looking to produce high-quality products. One common issue is the precision required in the design and manufacturing of molds. Even slight inaccuracies can lead to defects in the final products, which can incur additional costs due to rework and scrap. To overcome this, businesses should invest in advanced CAD software for detailed modeling and simulation, allowing for adjustments before physical production begins. Regular training for staff on the latest technologies and techniques can also enhance accuracy and efficiency.

Another significant challenge is maintaining the molds over time. Molds can wear out or become damaged with continual use, affecting production quality. Implementing a robust maintenance schedule is crucial for mitigating downtime and preserving mold integrity. Furthermore, utilizing high-quality materials for mold components can enhance durability and reduce replacement frequency. By establishing a culture of proactive maintenance and continuous improvement, businesses can streamline operations and boost their overall success in injection mold making.

Injection Mold Making: Common Challenges and Solutions

Optimizing Your Production Process for Cost-Effective Mold Making

In today's rapidly evolving manufacturing landscape, optimizing production processes for cost-effective mold making has become paramount for businesses aiming for success. With a shift towards sustainability, the metal forging industry has seen substantial growth driven by technological advancements and market demands. By 2032, the simulation software market is projected to expand significantly, addressing the crucial need for businesses to evaluate risks and enhance decision-making in production facilities. These tools allow companies to identify potential bottlenecks and weaknesses early in the development cycle, ultimately leading to more efficient operations.

Tips for achieving cost-effective mold making include investing in energy-efficient and eco-friendly machinery that meets stringent environmental regulations and consumer expectations. Advanced electric and hybrid injection molding machines not only reduce energy consumption but also significantly lower production costs. Moreover, embracing innovative technologies, such as 3D metal printing, can revolutionize traditional manufacturing processes by creating parts layer by layer, thus minimizing waste and enhancing sustainability.

As the automotive tools market continues to grow, projected to reach $608.8 billion by 2033, manufacturers must stay ahead of trends by adopting sustainable practices and integrating modern technology to remain competitive. By prioritizing these strategies, businesses can optimize their production processes, reduce costs, and align with global sustainability goals.

Related Posts

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

7 Essential Reasons Why Best Injection Moldable Plastics Are Your Ultimate Solution

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

The Future of Precision Injection Molding Innovations and Trends