Top Strategies for Maximizing Efficiency in Plastic Injection Molded Parts Production

The future of plastic injection molded parts production is poised for transformative advancements as manufacturers increasingly prioritize efficiency and sustainability. According to a recent report by MarketsandMarkets, the global plastic injection molding market is expected to reach $358.2 billion by 2027, growing at a CAGR of 5.7% from 2022. This growth is accompanied by an urgent need for industry players to adopt innovative strategies that not only enhance production efficiency but also address environmental concerns.

Techniques such as advanced automation, material optimization, and the integration of Industry 4.0 technologies are becoming crucial in meeting these challenges. As the demand for high-quality, cost-effective, and eco-friendly plastic injection molded parts rises, organizations must leverage these strategies to remain competitive in a rapidly evolving market landscape.

Understanding the Role of Material Selection in Injection Molding Efficiency

Material selection plays a crucial role in maximizing efficiency in plastic injection molded parts production. The choice of material not only impacts the manufacturing process but also affects the final product's performance, durability, and cost-effectiveness. Different polymers exhibit varying flow characteristics, cooling times, and thermal properties, which can significantly influence cycle times and energy consumption during molding. For instance, using a high-flow resin can reduce the injection pressure required and shorten the cycle duration, resulting in increased productivity.

Furthermore, understanding the application requirements is essential for selecting the right material. Factors such as mechanical strength, flexibility, and resistance to chemicals or environmental conditions should guide the selection process. For example, engineering-grade plastics offer superior performance for demanding applications, while commodity plastics are often sufficient for less critical components. Ultimately, collaborating with material suppliers and mold designers can ensure that the selected material aligns with the overall production goals, fostering enhanced efficiency and quality in the final molded parts.

Top Strategies for Maximizing Efficiency in Plastic Injection Molded Parts Production

| Material Type | Melt Flow Rate (MFR) | Cycle Time (seconds) | Production Yield (%) | Cost per Kg ($) |

|---|---|---|---|---|

| ABS | 15 | 30 | 95 | 2.00 |

| Polycarbonate (PC) | 12 | 40 | 92 | 3.50 |

| Nylon (PA) | 20 | 35 | 90 | 2.80 |

| Polypropylene (PP) | 25 | 28 | 93 | 1.20 |

| Polystyrene (PS) | 30 | 50 | 88 | 1.50 |

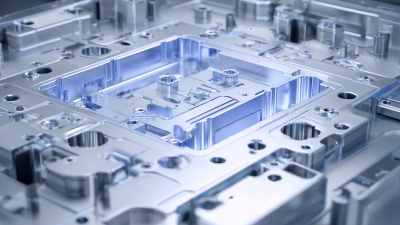

Streamlining the Design Process for Enhanced Mold Production

In the world of plastic injection molding, the design process serves as a crucial foundation for successful production. Streamlining this process not only enhances the efficiency of mold production but also significantly reduces lead times and costs. One effective strategy is the use of advanced CAD software to create precise 3D models of the parts. By enabling thorough visualization and simulation, designers can identify potential design flaws early, making adjustments before production begins. This proactive approach ensures that the molds produced are optimized for performance, leading to fewer defects and waste during actual injection processes.

Collaboration between designers and engineers is another key component in enhancing mold production. Implementing regular feedback loops throughout the design phase allows for real-time adaptations and improvements. Techniques such as Design for Manufacturability (DFM) can also be employed to ensure that the parts are not only aesthetically pleasing but also easy to manufacture. By considering the manufacturing capabilities and limitations during the design stage, teams can create molds that maximize efficiency, resulting in a smoother production flow and better overall quality of the final products.

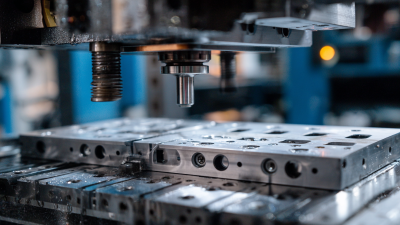

Implementing Advanced Technology for Precision and Speed

In the fast-paced world of plastic injection molding, the integration of advanced technology has emerged as a game-changer for enhancing both precision and speed in production. Utilizing state-of-the-art machinery equipped with automated controls, manufacturers can dramatically reduce cycle times while ensuring consistency in the quality of molded parts. High-precision robotics, for instance, not only streamline the assembly process but also minimize human error, leading to significant improvements in output efficiency.

Moreover, the adoption of simulation software allows for better planning and optimization of mold designs. This technology enables engineers to predict potential issues and make necessary adjustments before actual production begins. By capitalizing on these digital tools, companies can ensure that their injection molds operate at peak performance, further accelerating production timelines.

Real-time data analytics also play a crucial role, allowing manufacturers to monitor process parameters continuously and make data-driven decisions to enhance operation efficiency. Embracing these advancements is essential for companies aiming to stay competitive in the ever-evolving landscape of plastic injection molded parts production.

Optimizing Production Workflows to Reduce Waste and Downtime

In the competitive landscape of plastic injection molded parts production, optimizing production workflows is crucial for minimizing waste and reducing downtime. According to a report by the Society of Plastics Engineers, inefficiencies in the production process can lead to waste rates as high as 20% in some facilities. Implementing lean manufacturing principles enables companies to streamline operations, reduce cycle times, and enhance overall productivity. By adopting techniques such as value stream mapping and just-in-time production, manufacturers can identify bottlenecks and eliminate non-value-added activities, ultimately leading to a more efficient workflow.

Moreover, equipment maintenance plays a pivotal role in minimizing downtime. A study by the American Society for Quality indicates that unscheduled machine downtime can account for up to 25% of production time lost. Proactive maintenance strategies, such as predictive maintenance using data analytics, can significantly reduce equipment failures and ensure smooth operations. By integrating real-time monitoring systems, companies can detect potential issues before they lead to costly breakdowns, thereby maximizing operational efficiency and keeping production schedules on track. Reducing both waste and downtime not only improves the bottom line but also aligns with sustainability goals, increasing the overall appeal of manufacturers in today’s environmentally conscious market.

Case Studies: Successful Efficiency Strategies from Leading Manufacturers

In the competitive landscape of plastic injection molded parts production, leading manufacturers have implemented innovative efficiency strategies that have significantly boosted their productivity and reduced costs. One notable example is Company A, which introduced a real-time monitoring system for its injection molding machines. This allowed them to identify bottlenecks instantly and optimize machine utilization, leading to a 15% increase in output over six months. Such case studies underscore the importance of integrating technology into production processes to enhance operational efficiency.

Tip: Regularly analyze data from production lines to identify patterns and areas for improvement. Implementing predictive maintenance can minimize downtime and ensure equipment runs smoothly.

Another success story comes from Company B, which adopted lean manufacturing principles to streamline processes. By eliminating unnecessary steps and minimizing waste, they saw a remarkable reduction in cycle times by 25%. This not only improved their efficiency but also heightened product quality, resulting in greater customer satisfaction.

Tip: Foster a culture of continuous improvement by encouraging employee feedback and engagement. Training staff on efficiency techniques can lead to innovative solutions and increased morale.

Top Strategies for Maximizing Efficiency in Plastic Injection Molded Parts Production

Related Posts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Innovative Injection Molding Design Examples to Inspire Your Next Project

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

Common Challenges in the Best Plastic Injection Moulding Process

-

Achieving the Best Plastic Injection Molding Mold Standards Through Effective Design Techniques

-

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing