How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

In today's competitive manufacturing landscape, optimizing injection molding tooling processes has become imperative for companies striving for maximum efficiency and cost-effectiveness. According to a report by the Plastics Industry Association, the global injection molding market is projected to reach $300 billion by 2025, underscoring the significance of advanced tooling strategies in this booming sector. By refining tooling techniques, manufacturers can enhance production speed, reduce material waste, and improve product quality—a necessity in an era where speed-to-market is crucial. Recent studies have indicated that companies implementing efficiency-centered tooling solutions can achieve up to a 30% reduction in cycle times, resulting in substantial savings and increased output.

This blog will explore actionable strategies for optimizing your injection molding tooling processes, positioning your operations for future growth and success in this dynamic industry.

Understanding the Importance of Tooling Efficiency in Injection Molding

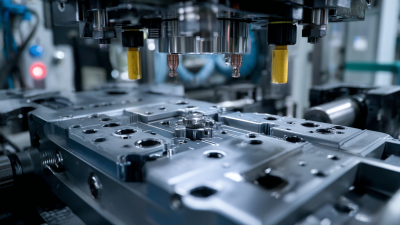

In the realm of injection molding, tooling efficiency plays a pivotal role in the overall success of the production process. Tooling refers to the use of specialized molds to shape materials, and optimizing this aspect can substantially enhance productivity and reduce costs. Efficient tooling means minimized cycle times, improved part consistency, and less wear and tear on equipment. By focusing on these elements, manufacturers can significantly elevate their output while maintaining high quality.

Understanding the importance of tooling efficiency allows companies to identify bottlenecks within their production lines. Regular maintenance, strategic design improvements, and the use of advanced materials can contribute to a more streamlined process. For instance, utilizing modular tooling can simplify repairs and replacements, ensuring that production remains uninterrupted. Additionally, investing in simulation software can help in predicting and resolving potential issues before they impact actual production, leading to smarter and more responsive manufacturing practices.

Five Key Factors Affecting Injection Molding Tooling Performance

When optimizing injection molding tooling performance, it's essential to consider several key factors that can significantly influence efficiency and output quality. First, effective mold thermal control is crucial for maintaining consistent temperatures throughout the process. This ensures optimal material flow and reduces the risk of defects, thus enhancing overall product quality.

Another factor to focus on is the melt temperature. For instance, recent findings suggest that maintaining a melt temperature of around 270 °C can lead to better performance, particularly in specialized applications such as IV hydrogen storage cylinders. Additionally, adjusting packing pressure and duration—ideal parameters being around 55 MPa and 20 seconds—can further optimize the process, resulting in reduced cycle times and improved product integrity.

Tip: Implementing simulation-driven design optimization can significantly reduce trial-and-error phases in mold production, minimizing waste and energy consumption while promoting sustainable manufacturing practices. Utilizing intelligent data-driven systems can also provide personalized optimization tailored to specific production needs, leading to a more efficient and effective injection molding process.

Ways to Reduce Cycle Times and Improve Production Flow in Tooling Processes

Optimizing cycle times is essential for enhancing production flow in injection molding tooling processes. One effective strategy is to implement advanced simulation tools that can predict potential bottlenecks before they occur. By using these simulations during the design phase of tooling, manufacturers can identify areas for improvement, thereby streamlining workflows and reducing downtime. Additionally, regularly reviewing and upgrading machinery can ensure that all equipment operates at peak efficiency, minimizing delays caused by outdated technology.

Another key approach to improving production flow is to adopt lean manufacturing principles. By eliminating waste and optimizing resource allocation, manufacturers can significantly reduce cycle times. This can be achieved through techniques such as just-in-time inventory management and continuous improvement practices. Encouraging collaboration among teams and fostering a culture of open communication also help in swiftly addressing issues that may arise during production, ultimately leading to a smoother and faster tooling process.

Leveraging Technology for Enhanced Precision and Tooling Management

In the evolving landscape of manufacturing, leveraging technology for enhanced precision and tooling management has become essential for optimizing injection molding processes. Recent studies indicate that companies adopting advanced technologies, such as computer-aided design (CAD) and simulation software, can reduce production time by up to 30% while improving part quality significantly. For instance, a report from Mordor Intelligence highlights that the global injection molding market is projected to reach $334 billion by 2027, largely driven by improvements in technology adoption that bolster efficiency.

Another significant advancement is the integration of Industry 4.0 practices, which includes the use of IoT devices and data analytics. According to a survey by Deloitte, manufacturers that implemented smart technologies reported a 20% increase in productivity. The ability to monitor tooling conditions in real-time and predict potential failures not only minimizes downtime but also extends the lifespan of the tools. With precision engineering enabled by these technologies, companies can achieve tighter tolerances and better surface finishes, ensuring higher quality output that meets rigorous industry standards.

Common Mistakes to Avoid for Optimizing Your Injection Molding Tooling Processes

When optimizing injection molding tooling processes, avoiding common pitfalls is essential for achieving maximum efficiency. One prevalent mistake is neglecting the design of cooling channels. Utilizing conformal cooling channels (CCCs) can significantly enhance cooling rates, as they maintain an equal distance from the mold surface, ensuring uniform temperature distribution. Research indicates that integrating CCCs can reduce cycle times by up to 25%, thus improving overall production throughput.

Another mistake often encountered is insufficient analysis of process parameters, which can lead to defects such as sink marks, shrinkage, and warpage. A recent study emphasized the importance of optimizing sequence valve gating (SVG) through the detection of melt fronts, allowing for a precise adjustment of valve gate positions. This method not only minimizes weld lines but also enhances product consistency and quality, ultimately leading to a more efficient manufacturing process. Adopting advanced methodologies like soft computing and particle swarm optimization can further refine these processes, addressing defects and ensuring high-quality outputs in plastic products.

Injection Molding Tooling Efficiency Optimization

This chart illustrates the average time or scrap rate in various key metrics related to injection molding tooling processes. Reducing these factors can lead to increased efficiency in production.

Related Posts

-

The Future of Precision Injection Molding Innovations and Trends

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Common Challenges in the Best Plastic Injection Moulding Process

-

7 Essential Reasons Why Best Injection Moldable Plastics Are Your Ultimate Solution