The Ultimate Guide to Mastering Best Polyethylene Injection Molding Techniques

In today's competitive manufacturing landscape, mastering polyethylene injection molding techniques is crucial for staying ahead in the industry. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $343.5 billion by 2026, with polyethylene being one of the most widely used thermoplastics due to its versatility and cost-effectiveness. As a dominant material in various applications, including packaging, automotive, and consumer goods, understanding the nuances of polyethylene injection molding can significantly enhance production efficiency and product quality. This guide will explore the best practices, innovations, and technical insights necessary for optimizing your polyethylene injection molding processes, ensuring that manufacturers can deliver high-quality products that meet global standards while maintaining competitive pricing.

Key Considerations for Selecting Polyethylene Materials in Injection Molding

When it comes to injection molding, selecting the right polyethylene material is vital for achieving optimal performance and durability. Polyethylene, categorized mainly into low-density polyethylene (LDPE) and high-density polyethylene (HDPE), offers varying properties suited to different applications. LDPE is known for its flexibility and toughness, making it ideal for products that require a degree of stretch and impact resistance, while HDPE boasts higher tensile strength and rigidity, which is advantageous for applications demanding robustness, such as containers and automotive parts. According to a 2021 report by Smithers, the global market for polyethylene injection molded products is projected to reach $25 billion by 2025, emphasizing the significance of selecting the right material for successful manufacturing outcomes.

Another critical factor is the processing conditions, which should be tailored to the specific type of polyethylene used. Research reveals that varying melt temperatures and injection speeds can significantly affect the final product's integrity and surface finish. For instance, maintaining an optimal melt temperature between 180°C and 220°C for HDPE can enhance flow characteristics and reduce defects like warping or incomplete filling. Moreover, proper material selection, including additives for UV stability and impact resistance, can significantly improve the longevity and performance of the molded part in its end-use environment. Incorporating these considerations into your polyethylene injection molding strategy can lead to superior product quality and extended service life.

The Ultimate Guide to Mastering Best Polyethylene Injection Molding Techniques

This bar chart illustrates the comparison of different types of polyethylene materials commonly used in injection molding, along with their respective properties such as tensile strength, elongation at break, and density. Understanding these facets is crucial for selecting the right material for effective molding.

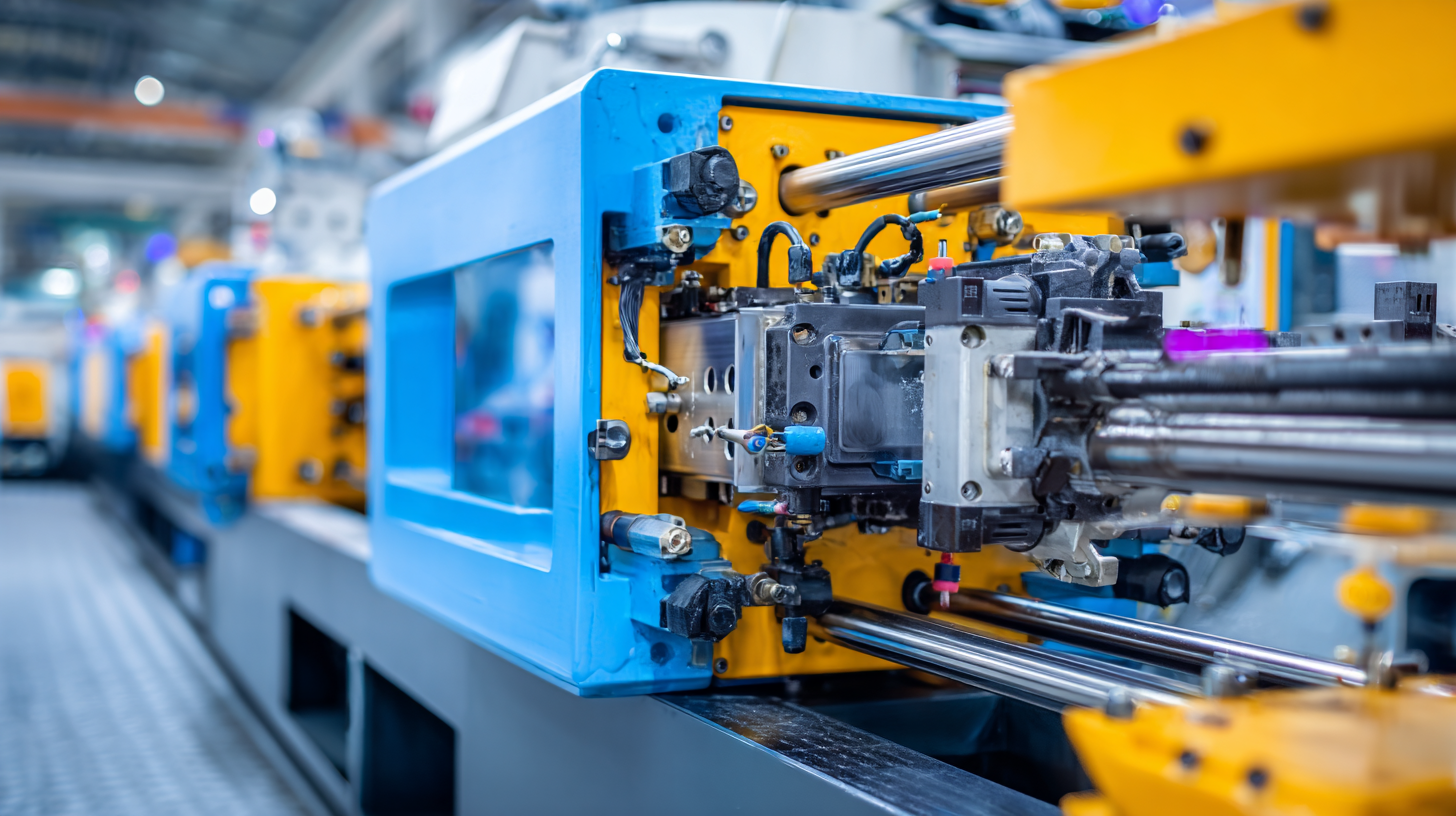

Essential Equipment and Tools for Effective Polyethylene Injection Molding

When it comes to mastering polyethylene injection molding, the right tools and equipment are essential for achieving high-quality results. According to a report by MarketsandMarkets, the global injection molding market is expected to reach $388 billion by 2025, highlighting the increasing importance of investing in advanced molding technologies.

Key equipment includes injection molding machines, which are the backbone of the process. Machines vary in size and capability; for instance, hydraulic machines are known for their reliability and versatility, while electric machines offer precision and lower energy consumption.

In addition to machines, auxiliary tools like mold temperature controllers and robotic automation systems play a pivotal role in enhancing production efficiency. The Society of Plastics Engineers identifies that maintaining optimal mold temperatures can reduce cycle times by up to 25%, directly impacting productivity. Furthermore, integrating robotics can streamline operations, delivering consistent and accurate part handling. As industries continue to prioritize efficiency and sustainability, the adoption of advanced polyethylene injection molding techniques—with the right equipment—will be crucial for manufacturers aiming to maintain a competitive edge.

Step-by-Step Process Checklist for Polyethylene Injection Molding

Polyethylene injection molding is a widely used method in the plastics industry, favored for its efficiency and versatility. To master this technique, following a step-by-step process checklist can significantly enhance the quality of your final products. According to the Plastics Industry Association, polyethylene accounts for nearly 34% of the total plastic production, underlining its importance in manufacturing sectors ranging from packaging to automotive components.

The first step in the process is material selection, where it's crucial to choose the right grade of polyethylene, such as HDPE or LDPE, depending on application requirements. Following this, precise machine settings must be configured, including temperature control, injection speed, and pressure settings, which can influence the flow and cooling of the molten material. Reports from the Society of Plastics Engineers indicate that optimizing these settings can reduce cycle times by up to 30%, significantly boosting production efficiency. Regular maintenance and calibration of the injection molding machine are also essential to ensure consistent output quality and minimize defects, which can lead to costly production downtime.

Common Challenges in Polyethylene Injection Molding and How to Overcome Them

Polyethylene injection molding is a popular manufacturing process, but it comes with its own set of challenges. One significant issue faced by manufacturers is the difficulty in achieving a uniform material flow. Inconsistent flow can lead to defects, such as voids or variation in wall thickness. To tackle this problem, it is crucial to optimize the design of the mold and ensure that the temperature settings are accurately calibrated. Implementing a well-planned cooling strategy can also significantly enhance material flow, leading to reduced cycle times and improved product quality.

Polyethylene injection molding is a popular manufacturing process, but it comes with its own set of challenges. One significant issue faced by manufacturers is the difficulty in achieving a uniform material flow. Inconsistent flow can lead to defects, such as voids or variation in wall thickness. To tackle this problem, it is crucial to optimize the design of the mold and ensure that the temperature settings are accurately calibrated. Implementing a well-planned cooling strategy can also significantly enhance material flow, leading to reduced cycle times and improved product quality.

Another common challenge is the occurrence of warping after the parts are ejected from the mold. This deformation can result from uneven cooling or residual stresses within the material. To minimize warping, engineers should consider using a more balanced cooling system and reinforcing the design with features that promote uniform heat distribution. Additionally, selecting the right grade of polyethylene resin, which offers better dimensional stability, can help mitigate this issue. By addressing these challenges proactively, manufacturers can improve the efficiency and effectiveness of their polyethylene injection molding processes.

Best Practices for Quality Control in Polyethylene Injection Molding Operations

In polyethylene injection molding operations, maintaining high-quality standards is essential for producing reliable products. The clamping device, plasticizing device, and drive unit play crucial roles in ensuring the efficiency and quality of the molding process. The clamping system secures the mold and must withstand the pressure exerted during injection, which emphasizes the importance of its proper maintenance and calibration. Operators should regularly inspect these systems for wear and tear to prevent inconsistencies in production.

Tips: One best practice is to monitor the temperature of the plasticizing device closely. Fluctuations in temperature can lead to uneven melting and affect the final product's integrity. Additionally, implementing a regular cleaning schedule for the injection molds can significantly reduce defects, ensuring that contaminants don’t compromise the quality of the molded items.

Another key practice involves conducting thorough quality control checks at every stage of the production process. This includes measuring the dimensions of produced components and evaluating their surface finishes. Establishing a standardized quality control protocol helps identify issues early and allows for quick adjustments, ultimately enhancing the overall efficiency and reliability of polyethylene injection molding operations.