Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

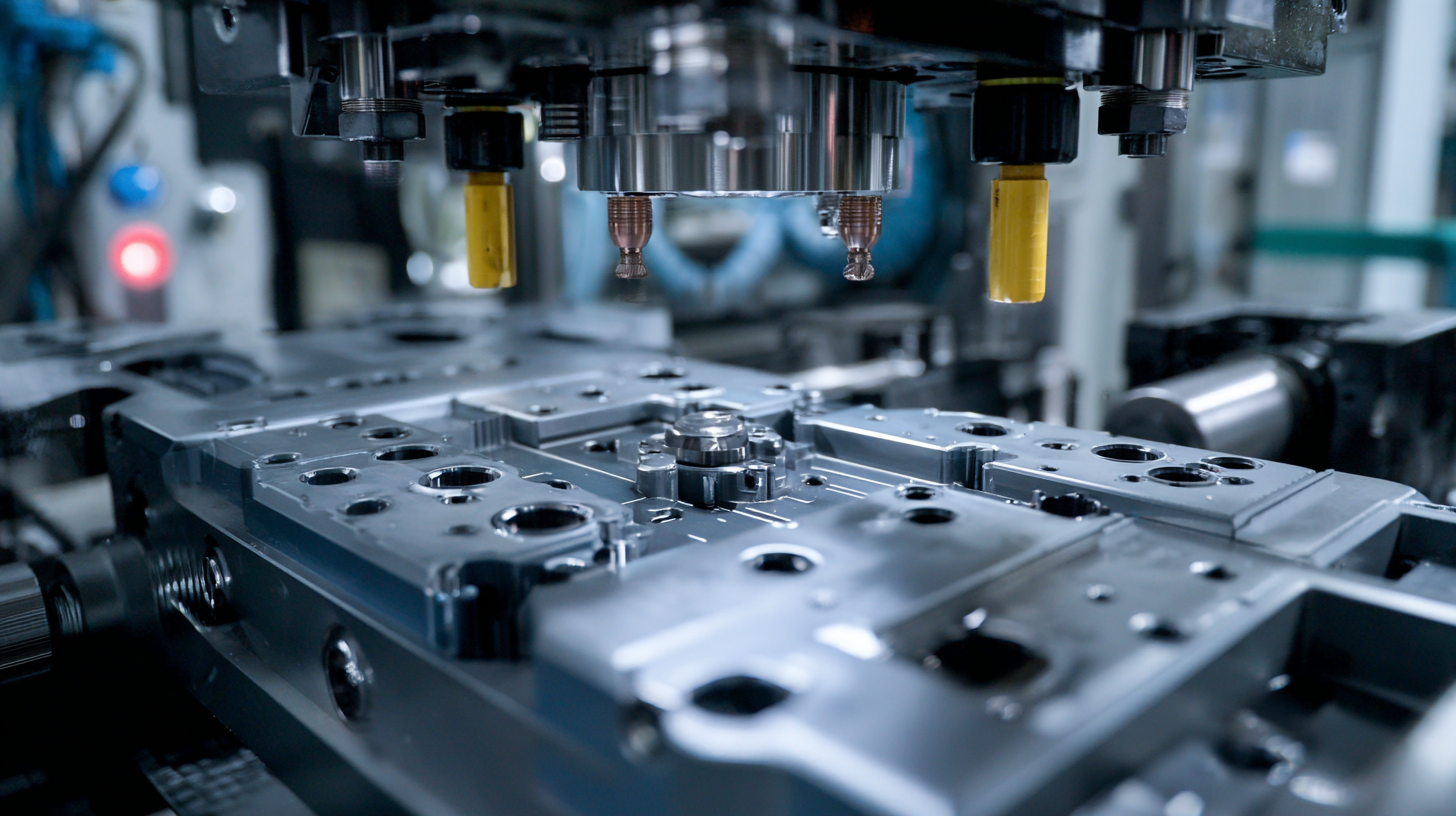

In today's rapidly evolving manufacturing landscape, the significance of innovative product features and applications in plastic injection mold tooling cannot be overstated. According to a recent report by MarketsandMarkets, the global plastic injection molding market is projected to reach $364.82 billion by 2027, growing at a CAGR of 5.5% from 2022 to 2027. This growth is propelled by the increasing demand for lightweight and durable plastic components across various industries, including automotive, consumer goods, and healthcare. As manufacturers strive to meet the changing needs of consumers and regulatory standards, understanding the unique features provided by advanced plastic injection mold tooling becomes essential.

This blog will explore a comprehensive checklist of critical elements to consider in selecting and utilizing plastic injection mold tooling to enhance product quality and production efficiency.

Exploring the Evolution of Plastic Injection Mold Tooling in China

The evolution of plastic injection mold tooling in China showcases its rapid advancement and adaptability in a dynamic market. With China's positioning as the largest manufacturer in the tool and mold industry, recent trends indicate a significant uptick in the sector driven by the positive developments in customer industries. As companies pivot toward specialized niches, like high-precision mold manufacturing and additive manufacturing, they can minimize costs and lead times, ultimately enhancing production efficiency. Recent data highlights that businesses focusing on additive technologies can reduce tooling times by up to 30%, making them highly competitive.

To stay ahead in this fast-paced environment, consider the following tips: First, invest in understanding the latest advancements in material selection and manufacturing technologies to enhance product quality. Second, keep an eye on market trends and shifts in demand; for instance, adapting products to respond to new needs, as seen during the pandemic, can drive business growth. Lastly, engage with local suppliers and manufacturers to leverage more sustainable practices, which are increasingly becoming essential in today's eco-conscious marketplace. These strategies will help businesses thrive in the evolving landscape of plastic injection mold tooling.

Innovative Product Features Driving Global Demand in Plastic Manufacturing

In the rapidly evolving world of plastic manufacturing, innovative product features are driving an unprecedented global demand for high-quality plastic injection mold tooling. According to recent industry reports, the global plastic injection molding market is projected to reach USD 345.77 billion by 2027, growing at a CAGR of 5.4% from 2020. This surge is propelled by advancements such as lightweight materials, enhanced durability, and eco-friendly options that cater to both consumer and industrial applications. Companies are increasingly focusing on the integration of smart technologies into their molding processes, which optimize efficiency and reduce waste.

To stay competitive, businesses must adopt strategies that harness these innovations. **Tip:** Embrace advanced manufacturing techniques such as 3D printing to create prototype molds, which can significantly streamline the development process and reduce costs. Additionally, investing in training for staff on the latest mold-making technologies can ensure that teams are equipped to leverage these advancements.

An essential aspect of this shift is the emphasis on sustainability. Reports indicate that over 60% of consumers prefer products made from recyclable materials. **Tip:** Consider using bio-based plastics in your designs, as this not only meets consumer demands but also aligns with global trends towards sustainable practices in manufacturing. By prioritizing innovative features and sustainable practices, businesses can tap into the thriving market of plastic injection molding.

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling - Innovative Product Features Driving Global Demand in Plastic Manufacturing

| Product Feature | Description | Application Area | Global Demand Trend |

|---|---|---|---|

| High Precision Molds | Molds designed with high tolerances to ensure accurate product dimensions. | Automotive components, electronic housings. | Increasing due to the demand for high-quality products. |

| Multi-Cavity Molds | Molds that allow for the production of multiple parts in a single cycle. | Consumer goods, packaging. | Rising demand due to cost-efficiency in production. |

| Hot Runner Systems | Systems that keep plastic molten to reduce waste and cycle time. | Complex parts requiring high volumes. | Steady growth as manufacturers seek efficiency. |

| Biodegradable Plastics | Materials that break down more easily in the environment. | Packaging, disposable products. | Rapid increase in demand due to sustainability trends. |

| Customizable Molds | Molds that can be tailored to specific product requirements. | Specialized industrial applications. | Increasing with the rise of niche markets. |

Quality Upgrades in Chinese Manufacturing: A Game Changer for Global Markets

The landscape of global manufacturing has experienced a significant shift in recent years, particularly with the rise of

Chinese manufacturing capabilities. Quality upgrades within this sector are not just enhancing production efficiency but are also redefining standards across the globe. These advancements result from a combination of technological innovation, investment in skilled workforce training, and adherence to international quality regulations. As a result, China is producing higher-quality plastic injection molds that meet stringent global specifications, making them increasingly competitive in international markets.

Moreover, these quality improvements in Chinese manufacturing have direct implications for businesses around the world. Companies sourcing from China can now benefit from more reliable products, reduced defect rates, and improved turnaround times. This capability allows global enterprises to innovate more rapidly without compromising on quality. The focus on quality in production processes, combined with cost-effective solutions, is a game changer, enabling companies to enhance their product offerings and meet consumer demands more effectively. As a result, China is not just a manufacturer but also a

key player in the global supply chain, driving the evolution of product development and market competition.

Applications of Advanced Plastic Injection Molding in Diverse Industries

The advanced applications of plastic injection molding are revolutionizing multiple industries through the effective use of materials like polyethylene (PE) and polypropylene (PP). These thermoplastics are characterized by their versatility, making them integral to various manufacturing processes, such as injection molding, blow molding, and profile extrusion. For instance, PE is extensively used for its lightweight and durability in packaging and containers, while PP provides excellent chemical resistance, ideal for automotive and consumer goods.

The growth in plastic processing machinery is significant, driven by the increasing demand for high-quality molded products. Forecasts indicate that the global market for plastic processing machinery will grow from $23.57 billion in 2025 to approximately $34.62 billion by 2032, reflecting a compound annual growth rate of 5.6%. As industries strive to reduce environmental impact, innovations in production methods are leading to a heightened focus on sustainable practices, thus reshaping the landscape of the plastic manufacturing sector. As technologies evolve, the focus on high-end products, alongside robust competition in the market, ensures that advancements in plastic injection molding will continue to shape diverse applications across various fields.

Sustainability and Efficiency: Future Trends in Plastic Injection Mold Tooling

The landscape of plastic injection mold tooling is rapidly evolving, driven by an increasing emphasis on sustainability and operational efficiency. A recent report by the International Plastics Forum highlighted that over 70% of manufacturers are seeking to enhance their sustainability practices, promoting the use of biodegradable materials and energy-efficient machinery. This shift is not merely a trend but a necessity, as consumer demand for eco-friendly products continues to rise, with 57% of consumers willing to pay more for sustainable goods.

In addition, advancements in technology are enhancing the efficiency of plastic injection mold tooling processes. According to a study by the Society of Plastics Engineers, modern tooling techniques can reduce cycle times by up to 30%, leading to significant cost savings for manufacturers. By integrating smart manufacturing technologies such as IoT and AI, companies are optimizing production lines and minimizing waste. These innovations not only contribute to sustainability goals but also improve competitiveness in a market that increasingly values both environmental responsibility and operational efficiency.